We built xcPEP to reflect real-world manufacturing, not generic averages. Unlike legacy tools, our platform bases every cost model on detailed manufacturing logic and region-specific rates. Through our integrated xcPROC data hub, we ensure all material prices, labor costs, and machine rates are "verified"-continuously refreshed and validated. This means your estimates will always mirror current market conditions and you'll never have to second-guess outdated, "supplier market" data again.

xcPEP vs Legacy Costing Software

Why 'black-box' automation fails. See how xcPEP's transparent, data-driven "glass-box" approach delivers real-world accuracy.

Full Feature Comparison

A detailed breakdown of how xcPEP's modern architecture compares to rigid, black-box parametric tools.

| Capability / Feature | xcPEP | Legacy costing / parametric tool | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Core costing & process depth

|

|||||||||||||||||

Cost model architecture (UI-layer models) Key Differentiator

|

|||||||||||||||||

Data inputs, RM, machine hour and xcPROC service

|

|||||||||||||||||

Performance, usability and ownership

|

|||||||||||||||||

API and integration capabilities

|

|||||||||||||||||

Security, compliance and deployment

|

|||||||||||||||||

Commercial, support and rollout

|

|||||||||||||||||

Note: xcPEP models are delivered through the UI and updated centrally by ASI. Customers can raise tickets to get new or variant process models. These are released as per the defined turnaround time and become visible in the customer tenant in real time.

The Problem with "Black Box" Costing

Manufacturers across automotive, off-highway, home appliance, electronics and machinery sectors have long relied on geometry-based costing software for should-costing and DFM analysis. However, many users have noted drawbacks.

Common complaints include limited data accuracy, opaque “black-box” calculations, a steep learning curve, high complexity and cost, and heavy reliance on expert cost-engineering teams.

In short, users report that achieving accurate, defendable cost estimates with these tools can be slow, resource-intensive, and opaque – especially when projects demand region-specific data or fast implementation.

Key Pain Points of Legacy Software

Data accuracy and currency: Users wish geometry - based costing tools offered more up-to-date, location-specific material and labor rates. One engineer noted the tool’s database should better reflect “supplier market” costs to yield “closer to accurate/actual costing”.

Limitation in costing of Proprietary Parts and PCBs: Tools that rely on 3D models falter when costing proprietary parts and completely struggle with the complexities of PCB costing, where traditional 3D models are insufficient for accurate manufacturing cost analysis.

Transparency and traceability: The software has been described as a “black box”, where it’s “difficult to find the source and formula behind” calculated cycle times and costs. This lack of visibility makes it hard to defend estimates.

Performance and speed:: Because the tool is deployed on-premise, users report that almost everything takes too long to load. Screens open slowly, modeling workflows lag, and even basic actions are delayed. Local hardware limitations make the entire system feel heavy and inefficient.”

Implementation complexity: Deploying a model-driven cost analysis system often demands large cost-engineering teams or consultants. Upgrades and custom integrations can be “painful” and require expert support.

Pricing and cost of ownership: The platform’s subscription and maintenance fees can be steep. Reviewers explicitly called out the “expensive” licensing and need for paid add-ons, forcing companies to build large business cases for approval.

Limited process coverage: Finally, some users find CAD-driven cost modeling platform offers incomplete process libraries. Reports mention missing capabilities for specialty parts (e.g. certain molds, fluids, assemblies) and an expanding machine database requirement.

How xcPEP Addresses Every Pain Point

A detailed breakdown of how xcPEP's modern architecture compares to rigid, black-box parametric tools.

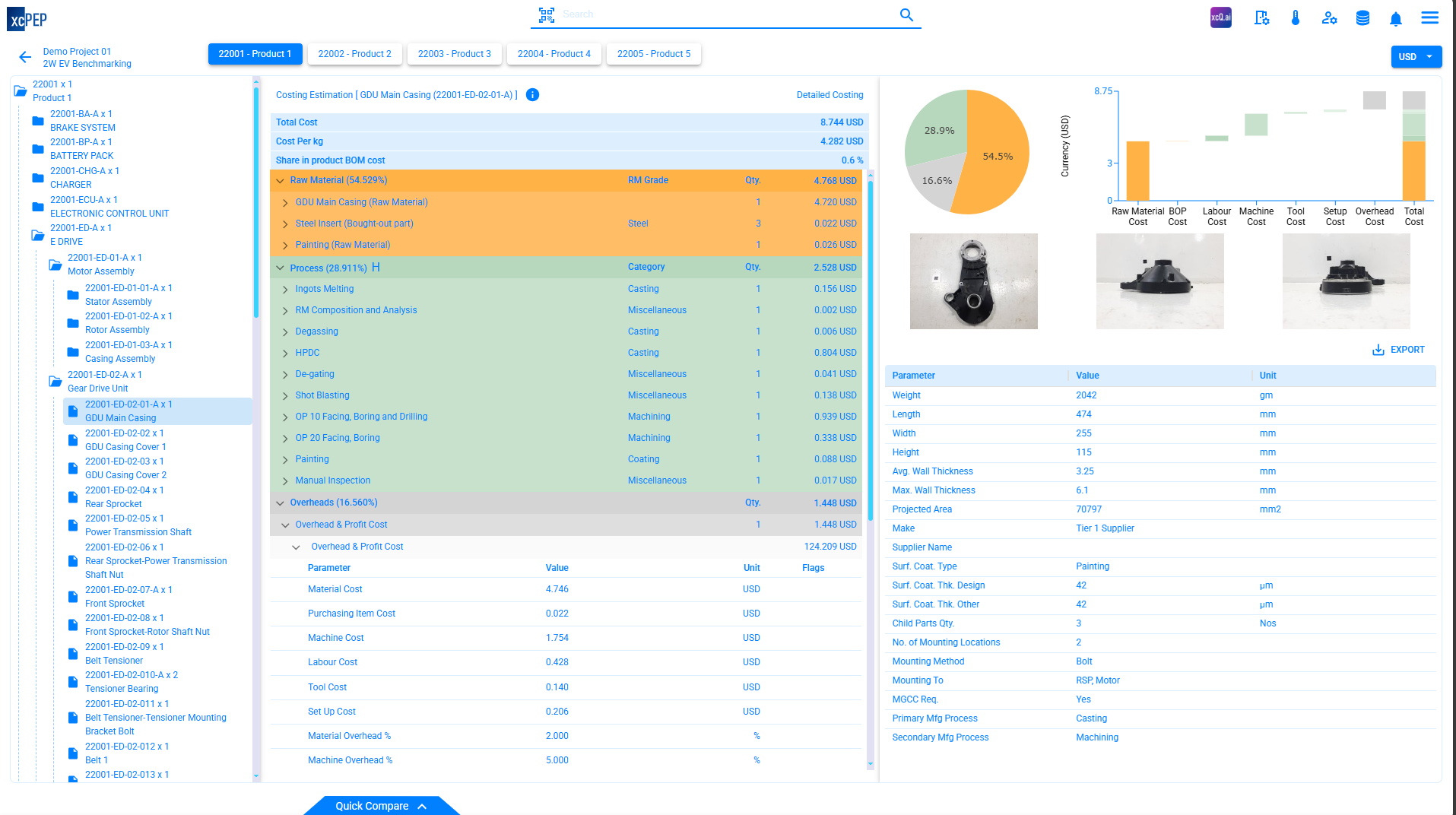

1. Real-World Process Accuracy

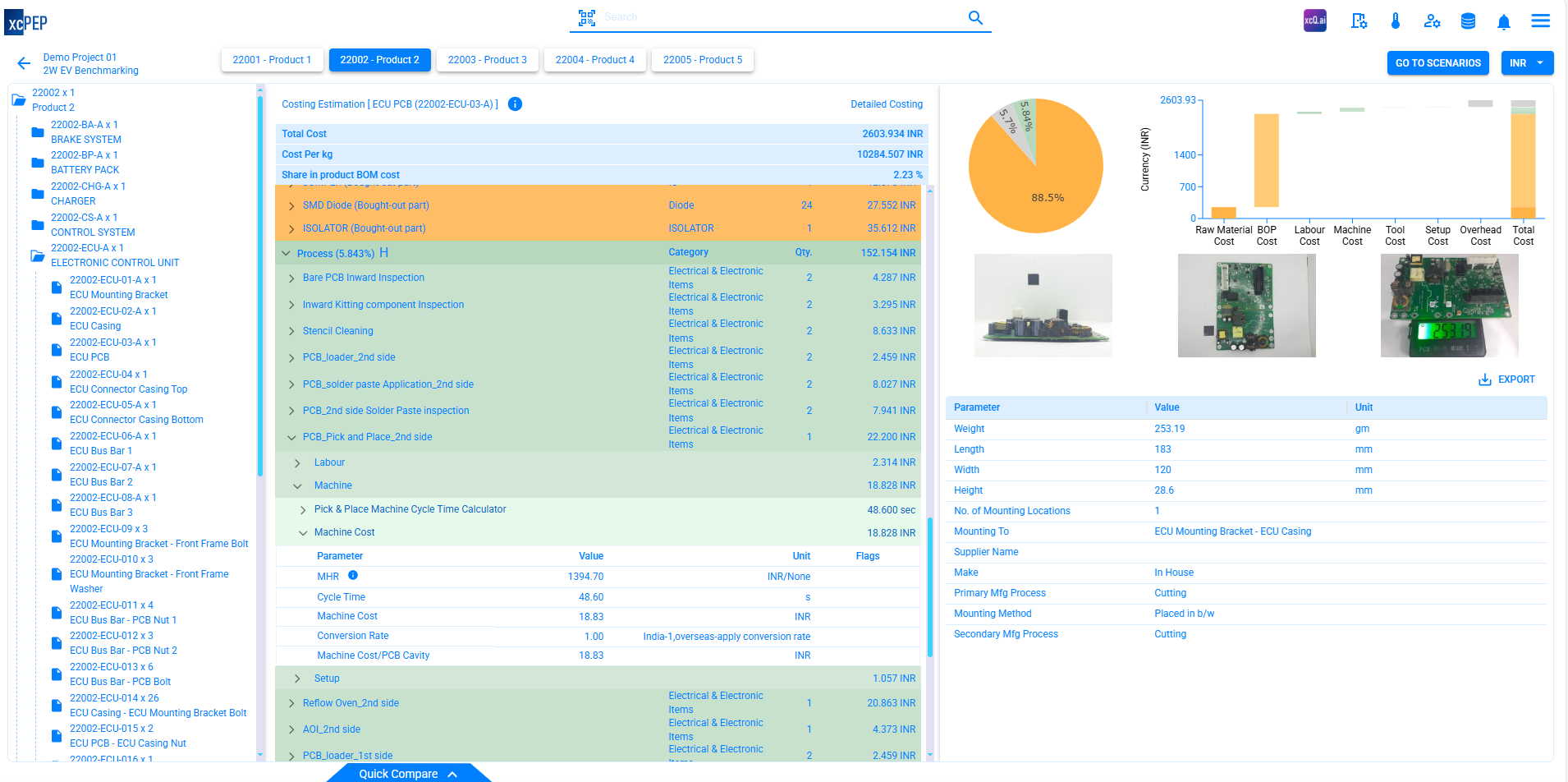

2. Comprehensive Costing (Electronics & Proprietary)

xcPEP is your robust alternative to 3D-based tools that fail on critical components. We designed the platform for total flexibility, allowing you to accurately cost proprietary parts using our deep manufacturing logic-even without an internal 3D model. Furthermore, we provide specialized and accurate PCB costing capabilities that account for unique fabrication processes, material layers, and component placement. This gives you a complete, reliable, and holistic cost estimation across your entire bill of materials, overcoming the limitations of traditional tools.

The screenshot above shows the detailed costing of an electronic PCB as done in xcPEP.

3. Full Transparency and Traceability

We eliminate the "black-box" for good. xcPEP is built with full transparency into every calculation and input, allowing your cost engineers to drill down into each cost driver (materials, labor, overhead, etc.). We combine structure, transparency, and part-level traceability to ensure every model is 100% defensible. If a manager asks, "Why did cycle time jump?" you can trace the exact parameter or formula that changed-a feature critically lacking in opaque legacy tools.

xcPEP provides clear, transparent visibility into all cost details-allowing users to trace every number.

4. Intuitive Cloud-Native Design

We built xcPEP from the ground up as a cloud-native platform for speed and performance, even with complex assemblies. This architecture eliminates the slow, heavy deployments of legacy desktop tools. Our interface is intuitive, with a shorter learning curve designed specifically for cost engineers and sourcing teams, not just designers. Training and all updates are built directly into the SaaS offering, so you get new features and data automatically-no more painful version upgrades.

5. Reduced Dependence on Large Teams/Consultants

xcPEP is designed to empower your team, not create a dependency on consultants. The platform is modular, easy to tailor to your specific operations, and includes built-in guidance. We also offer a "Build-Operate-Transfer" (BOT) service where our own ASI cost engineers help set up your system (configuring it to your BOMs and data standards), then train your in-house team to run it. This empowers you to run a stand-alone cost lab with minimal outside support, reducing the professional services burden required by legacy tools.

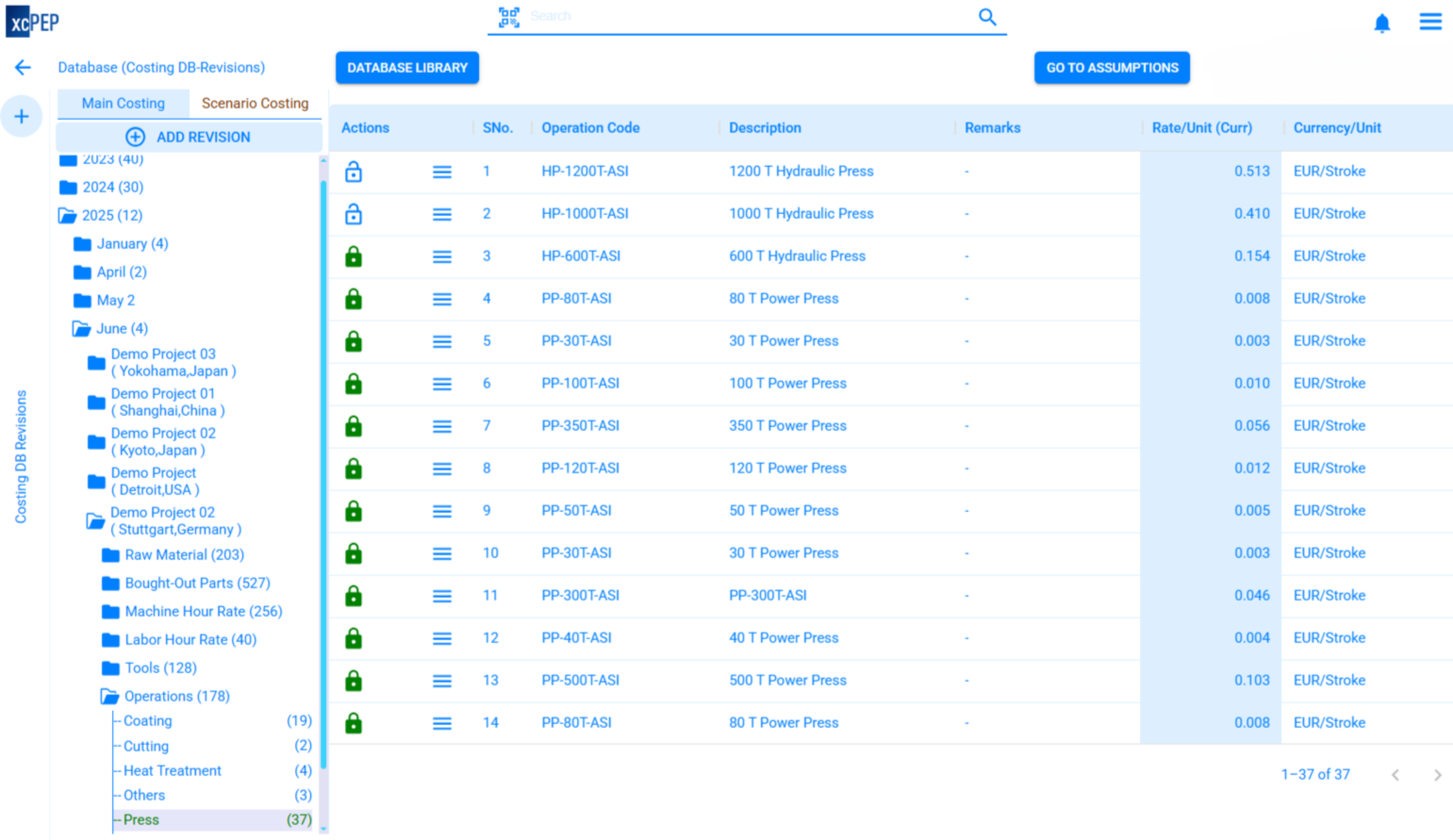

6. Comprehensive Process & Industry Coverage

Our process library covers the industries legacy tools often forget. We provide wide-ranging, real-world process models for automotive, off-highway, home appliances, and consumer electronics. This breadth ensures you can model complex or niche parts (like special castings or electronics assemblies) accurately and without workarounds. Our templates and calculators are designed to match your real-world shop-floor practices.

Part of xcPEP’s operations database, including detailed machine rates for various press operations.

7. Lower Total Cost of Ownership

Our modern SaaS approach translates directly into lower costs, at about one-third the cost of ownership of legacy software. We achieve this through a lean cloud architecture, automated updates, and minimal onsite infrastructure. Your subscription and support fees are dramatically lower than the high annual costs of legacy deployments. By cutting license and hardware costs by roughly two-thirds, xcPEP fits smaller budgets while still delivering high-end capabilities.

Key Benefits for Users

Discover how xcPEP empowers your team with unparalleled accuracy, transparency, and efficiency in cost engineering.

Faster, accurate cost targets

Switching to xcPEP enables teams to achieve reliable cost targets for own & bought out parts with less effort. The platform eliminates guesswork and accelerates should-cost workflows.

Designed for key use cases

xcPEP supports critical use cases like early design cost validation, supplier negotiation prep with detailed “fact packs,” competitor product benchmarking, and managing cost-reduction programs.

Transparent, data-driven negotiations

Every cost model in xcPEP is backed by data and logic. Sourcing teams can negotiate with greater clarity using detailed breakdowns that clearly explain each cost driver and assumption.

Defendable cost assumptions

Since every input is traceable, teams can confidently defend their cost targets during internal design reviews or external supplier meetings. There’s no black box - every number can be explained.

Easy to scale across teams

xcPEP’s flexibility allows even smaller OEMs and Tier suppliers to build and operate their own in-house cost labs - without the need for a large cost-engineering department or expensive IT support.

Solves real issues for users

xcPEP directly addresses challenges commonly reported in public reviews of parametric costing software, such as lack of transparency, difficulty in customizing models, and high ownership costs.

Up-to-date regional cost data

The platform uses current, localized manufacturing data - which means estimates reflect actual conditions and market rates, improving should-cost accuracy across global sourcing regions.

Transparent logic-driven models

Unlike black-box solutions, xcPEP gives users full visibility into how each cost is calculated. This builds trust across engineering, sourcing, and finance teams.

Cloud-native and IT-light

Being cloud-native, xcPEP avoids the heavy IT setup or maintenance required by traditional installed software. Teams can onboard faster and avoid delays caused by IT bottlenecks.

Fewer specialists needed

Because xcPEP is intuitive and supported by built-in expert logic, it requires fewer internal cost specialists to operate. Teams become self-sufficient faster and stay lean.

Lower licensing & operating costs

Customers report cutting licensing fees to nearly one-third of legacy platforms - while reducing the cost engineering headcount by up to 50%.

Built for modern cost engineering

For manufacturing teams tired of outdated and rigid costing tools, xcPEP offers a practical, modern alternative. It supports faster workflows, clearer insights, and a much lower total cost of ownership.

Ideal for complex industries

xcPEP shines in industries where cost detail and traceability matter most - including automotive, off-highway, consumer electronics, appliances, and industrial equipment.

Streamlined Team Collaboration

Move beyond scattered spreadsheets. xcPEP provides a central hub for engineering, procurement, and finance to collaborate on cost models and scenarios in real-time.

Strategic Supply Chain Insights

Leverage your cost data to make smarter sourcing decisions. Understand vendor capabilities and identify new cost-saving opportunities across your entire supply chain.

Real-Time Data & AI-Driven Insights

Integrate live manufacturing data and leverage AI to provide dynamic cost predictions. xcPEP continuously learns from market shifts, ensuring your cost models are always accurate and forward-looking.

The "Black Box" vs. The "Glass Box"

Legacy automated costing is a guess. We blend automation with collaborative adaptation for a clear, accurate, and defendable result.

A 5% error in cost calculation leads to a 50% error on the EBIDTA level.

The Black Box: Pure Automation

Automated costing engines that rely exclusively on CAD or preset formulas. This "one-size-fits-all" approach glosses over nuances, resulting in "black box" outputs that lack transparency.

- A machining process in Germany differs vastly from one in Southeast Asia.

- Electrical component sourcing and assembly vary from one industry vertical to another.

- Raw material availability can modify manufacturing processes across the world.

The Glass Box: Deep Adaptation

xcPEP blends automation with collaborative customization. We work with your teams to build detailed, tailored cost templates that reflect your actual production processes, quality, and vendor landscape.

- Higher Accuracy: Cost estimates mirror your specific manufacturing environment and supply chain.

- Flexibility & Control: Easily adapt templates as suppliers, materials, or methods evolve.

- Speed & Scalability: Once tailored, costing becomes a rapid, scalable exercise for all teams.

- Better Negotiation Power: Transparent, defendable cost breakdowns lead to effective supplier discussions.

See the "Glass Box" in Action

The "Glass Box" isn't just a concept. See how xcPEP delivers real-world accuracy, flexibility, and negotiation power in this 2-minute overview.

Industries we serve

Delivering granular cost intelligence for the world's most complex manufacturing environments-from design to delivery.

Automotive

Granular models for EV powertrains, body-in-white, interiors, and complex Tier 1 assemblies.

Off-Highway

Models for heavy fabrication, hydraulic systems, and low-volume specialty components.

Consumer Electronics

Precision costing for complete BOMs, from PCBs and display modules to high-volume tooling.

Home Appliances

Breakdowns for motors, compressors, sheet metal, and complex electro-mechanical systems.

Medical Devices

Costing for high-tolerance manufacturing, biocompatible materials, and critical regulatory compliance.

Industrial Equipment

Analysis of custom machinery, MRO, fabricated components, and industrial-grade control systems.

Our Products

Purpose-built for real world, transparent, and scalable should-costing. Explore xcPEP, our cloud-native should-costing software, and xcPROC, our structured cost database for accurate and scalable should-costing.

Start the Conversation

Email our team to request a custom demo or discuss enterprise SaaS licensing for xcPEP.