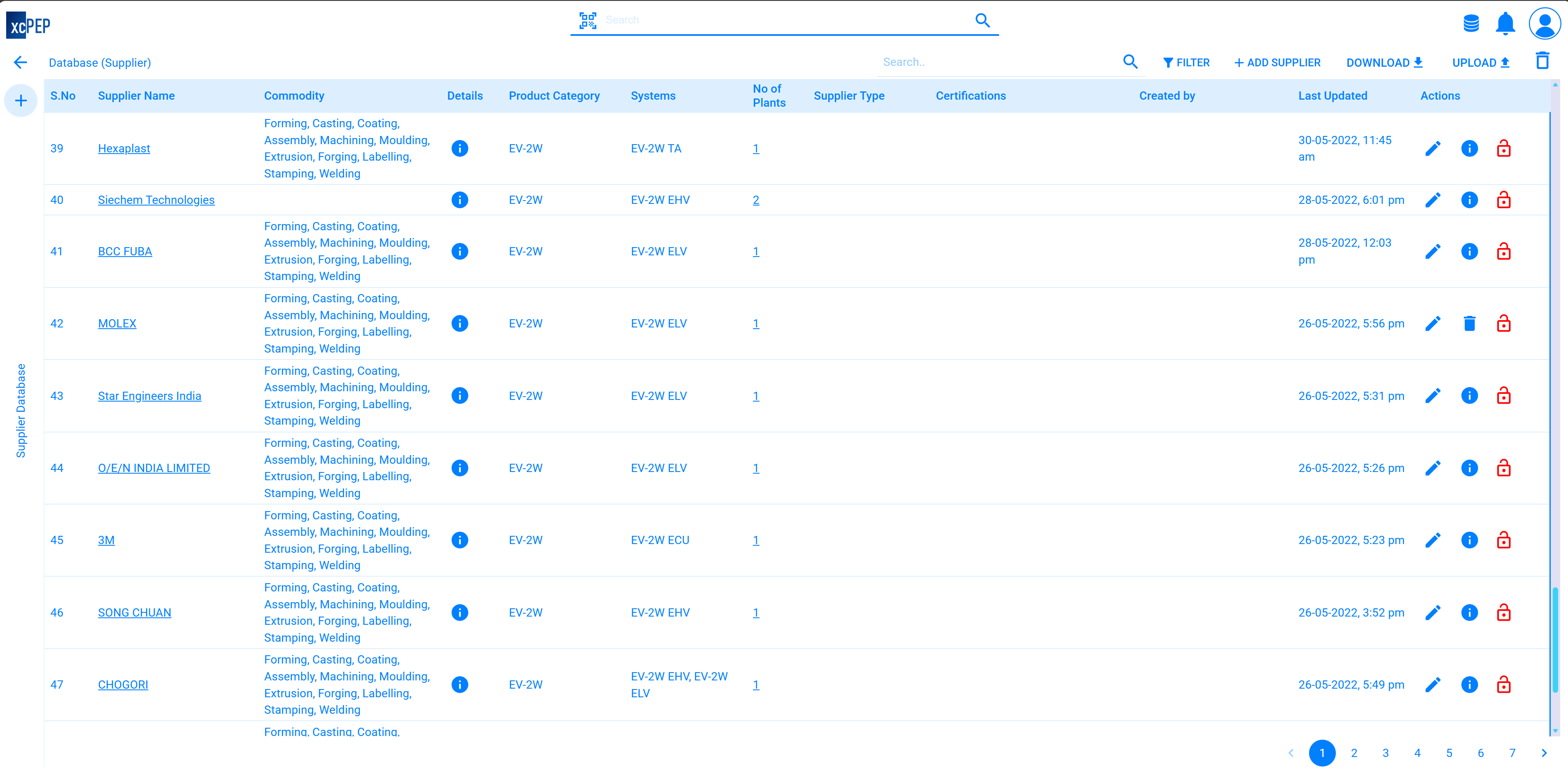

xcPROC is the centralized database engine powering xcPEP. Built entirely by xcPROC data research team, each database is meticulously curated to be city-specific and time-specific.

-

Cost Models

Structured models for manufacturing logic, not static averages.

-

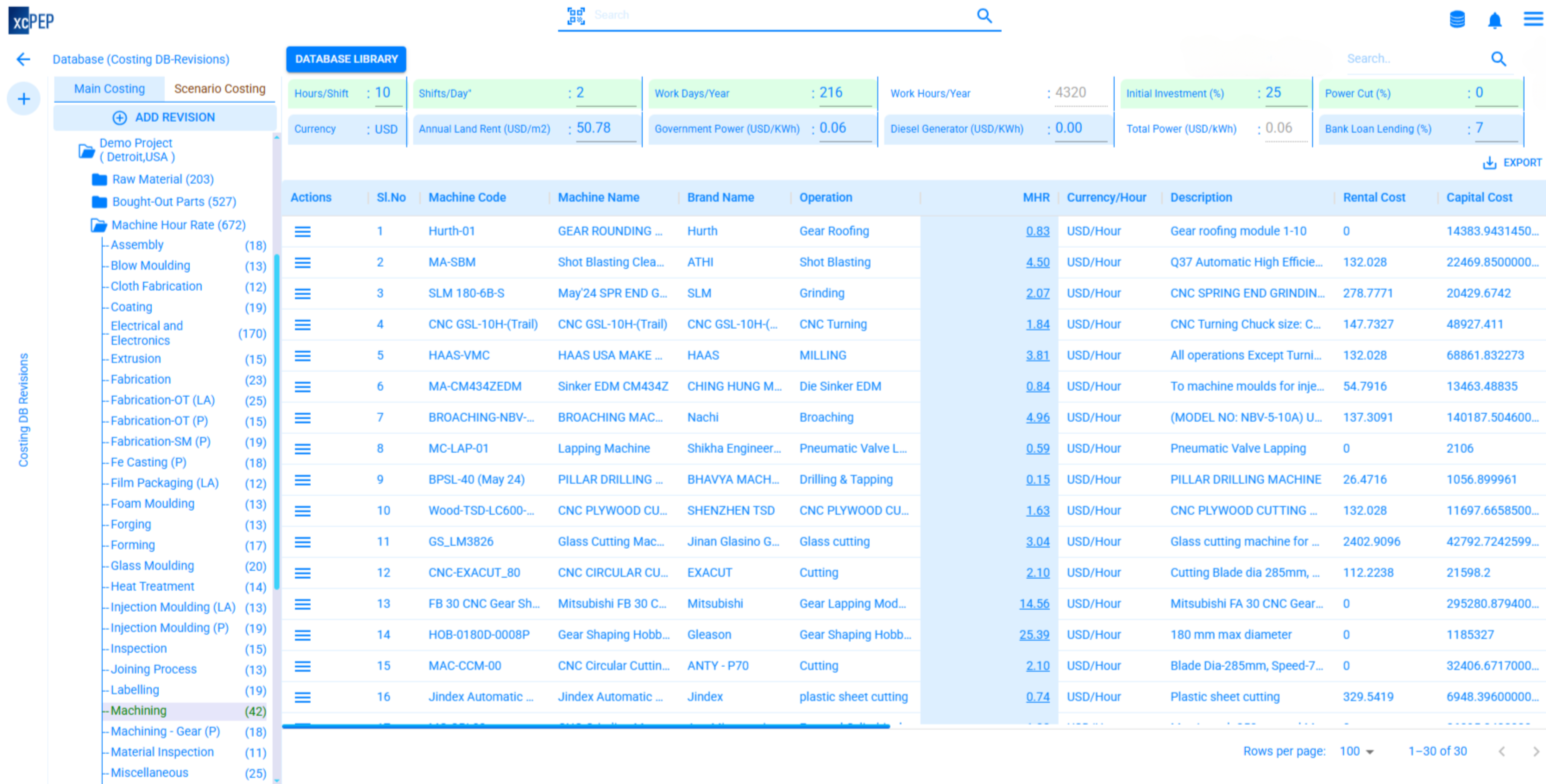

Machine Hour Rates

Precise MHR calculations based on equipment, utilities, and more.

-

Labor Hour Rates

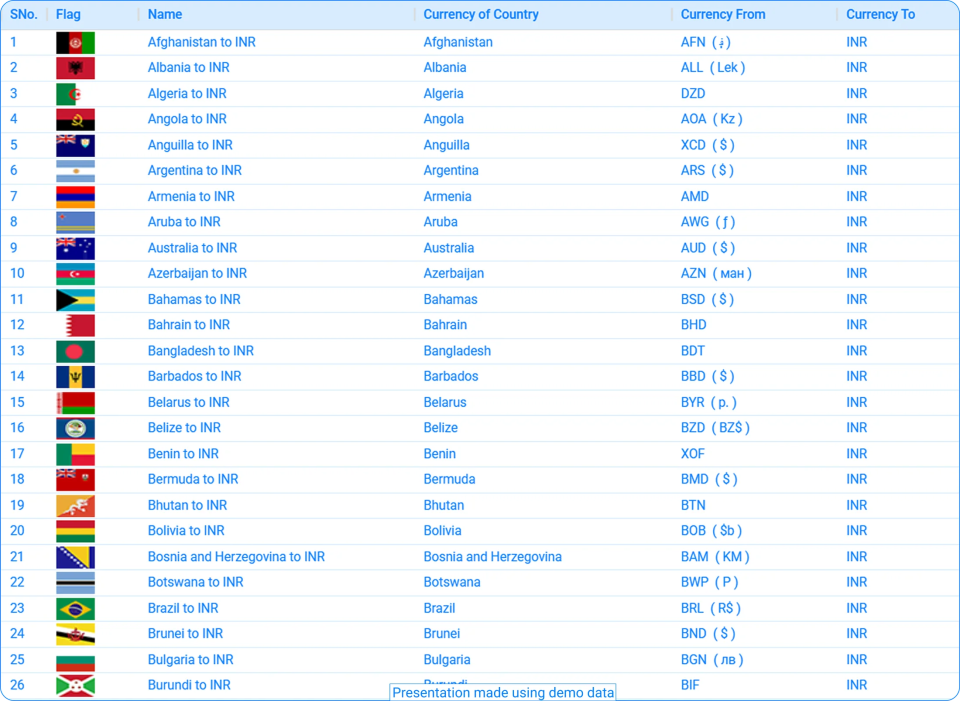

Region-specific wage data for skilled, semi-skilled, and unskilled labor.

-

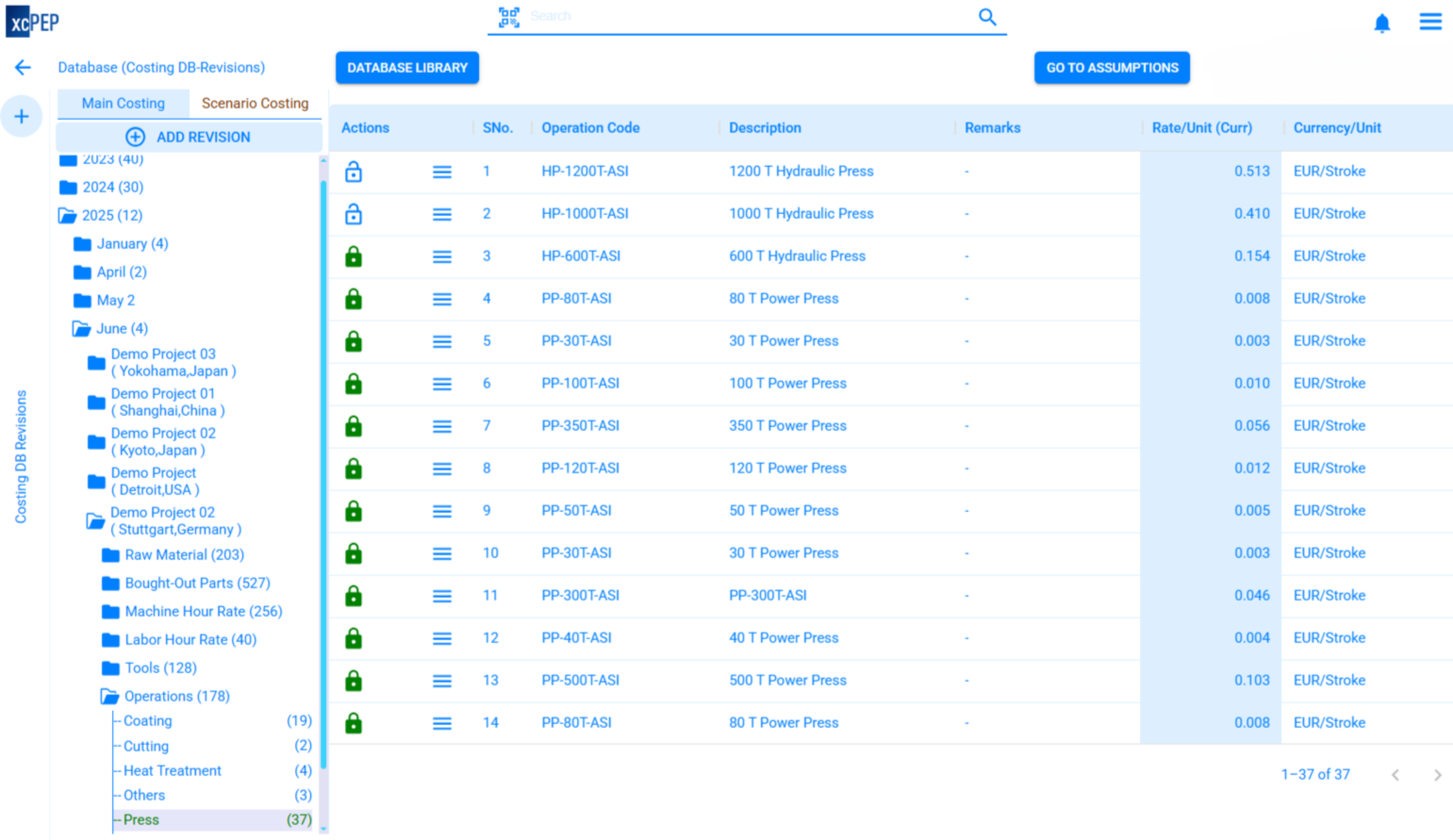

Operation Based Rates

Granular cost data for standard manufacturing processes.

-

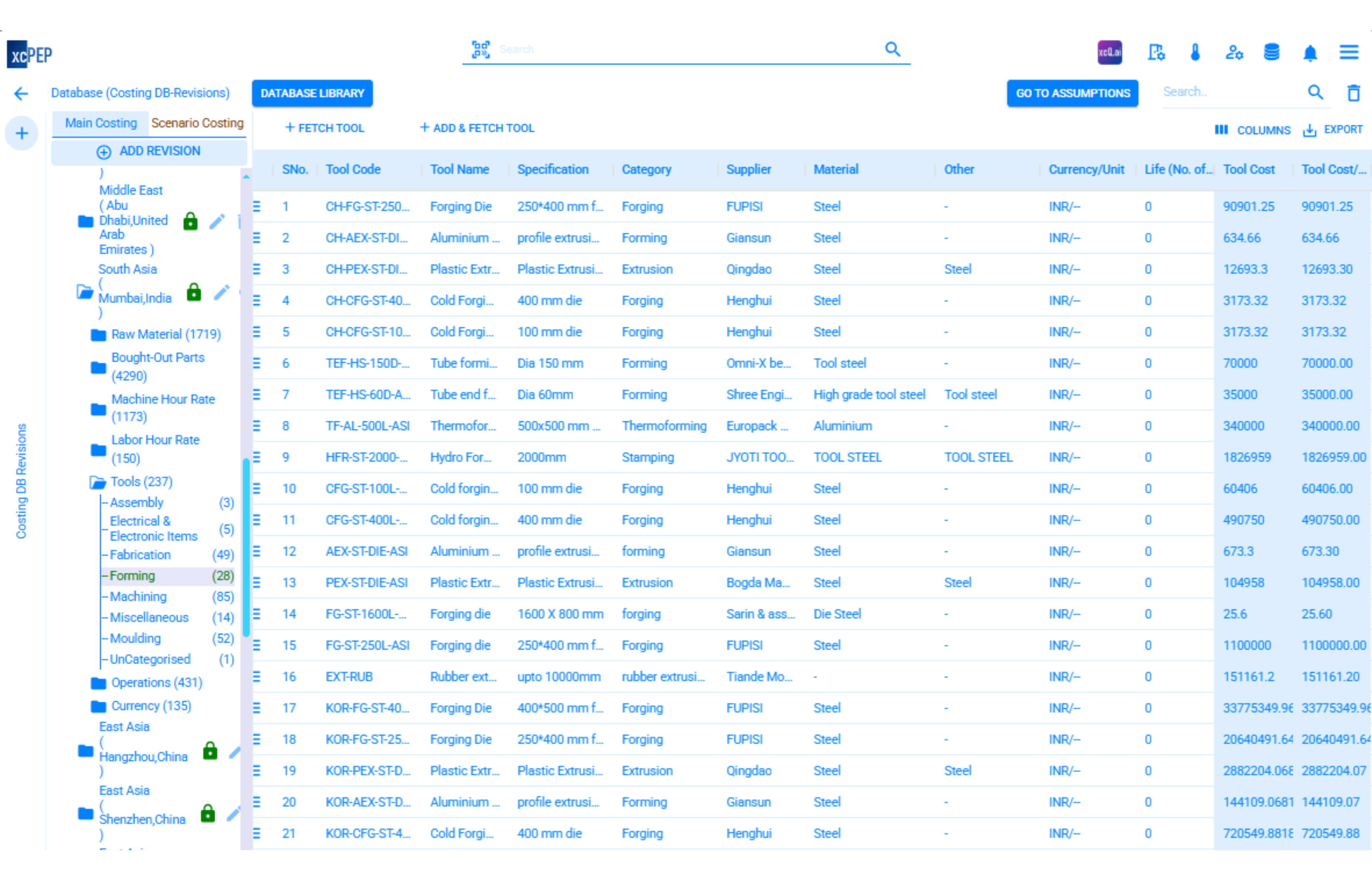

Bought Out Part Rates

Curated pricing for standard components, fasteners, and materials.