A Platform Built for Clarity

See how xcPEP generates an accurate should cost from your most complex parts or drawings.

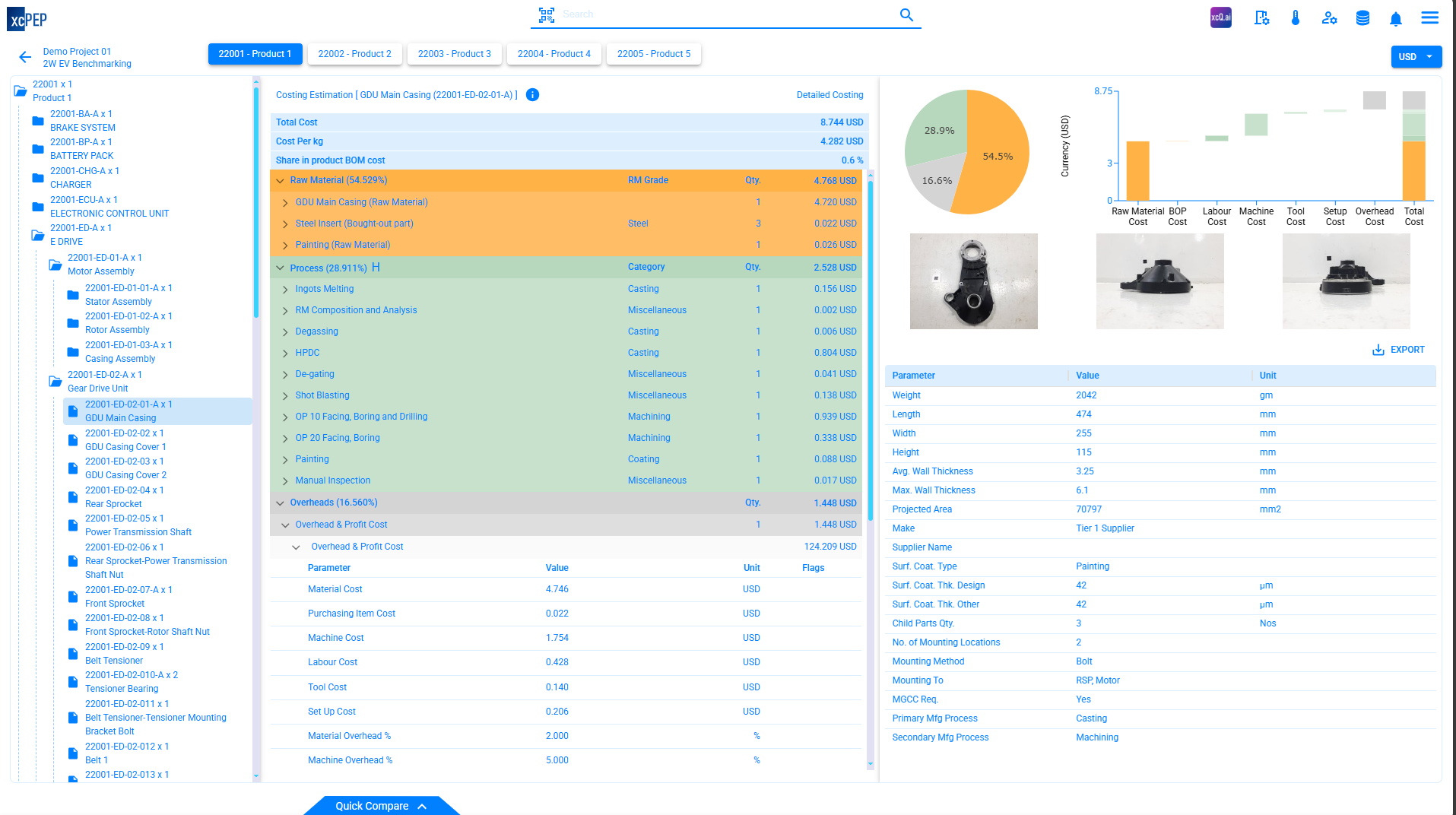

Cost from Drawings or Part Teardown

xcPEP gives you complete flexibility to build your Bill of Materials from what you have. Capture parameters from a manufacturing drawing or from a physical part teardown.

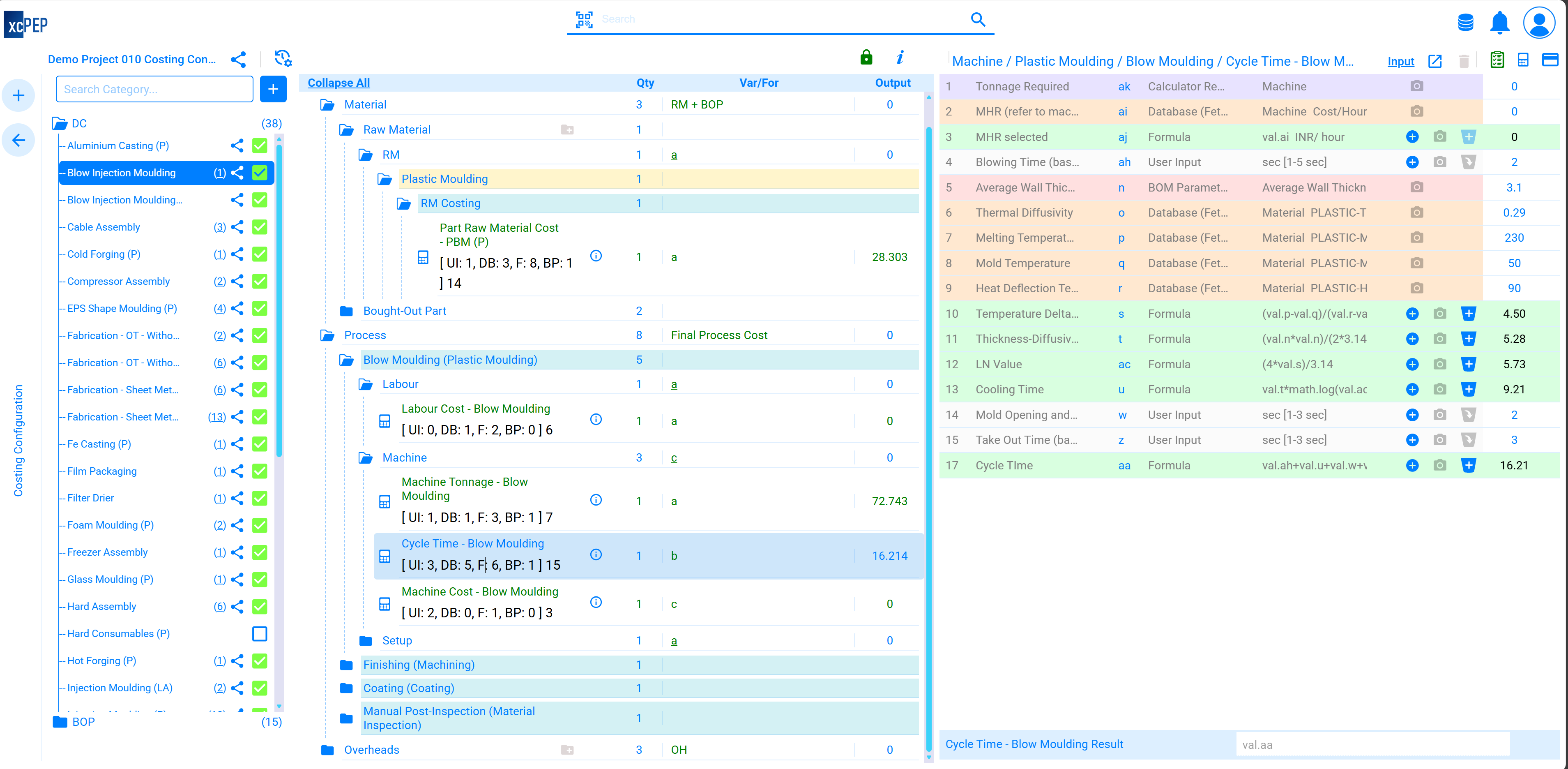

Configurable Cost Models

This is not a black box. Work with structured, editable cost models. Adjust logic, equations, material usage, cycle time, and tool life to match your specific manufacturing reality.

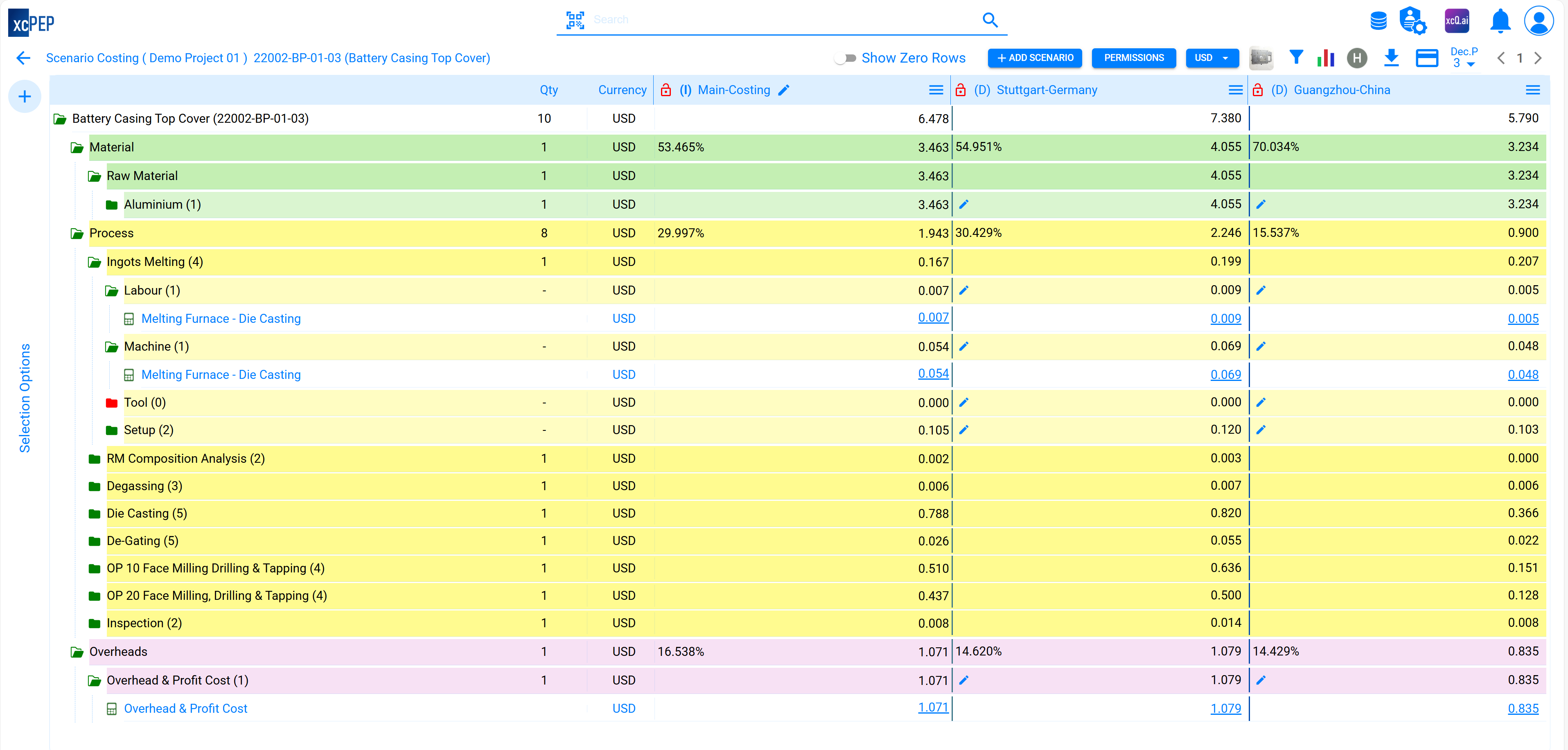

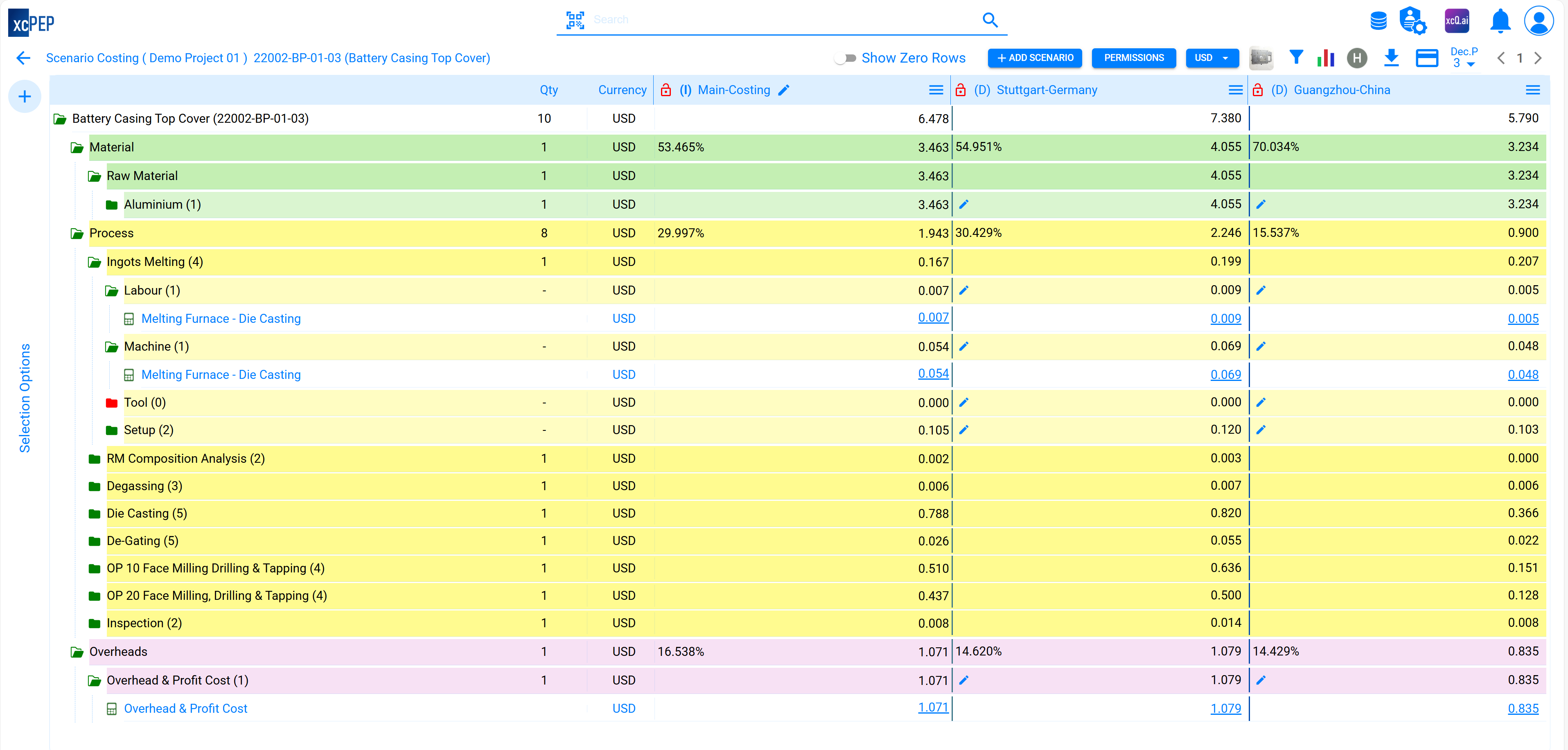

Scenario Simulation & Comparison

Create unlimited "what-if" scenarios by modifying volume, material, or supplier location. Compare cost deltas side-by-side to find the optimal sourcing strategy.

API-Based Integration

The platform provides APIs to exchange high volume data bi-directionally. This lets you pull in data like BOMs from your PLM or ERP systems, and seamlessly send cost outputs back to them, or to your internal analytic and AI tools.

From Drawing or Physical Part to Accurate Should Cost

Analyze Your Part

Develop your Bill of Materials (BOM) by analyzing a manufacturing drawing or conducting a physical part teardown.

Map & Model

BOM data from manufacturing drawings or teardowns is instantly mapped into your team's custom, editable cost models.

Connect & Cost

Your model is instantly populated with curated, region-specific data from the xcPROC hub to create the initial should cost.

Simulate & Compare

Run unlimited "what-if" scenarios for machines, labor, or volumes and compare them side-by-side.

Act & Integrate

Generate "Fact Packs" for vendor negotiations or push the final cost data via API to your internal ERP/PLM systems.

Powered by xcPROC: The Data You Can Trust

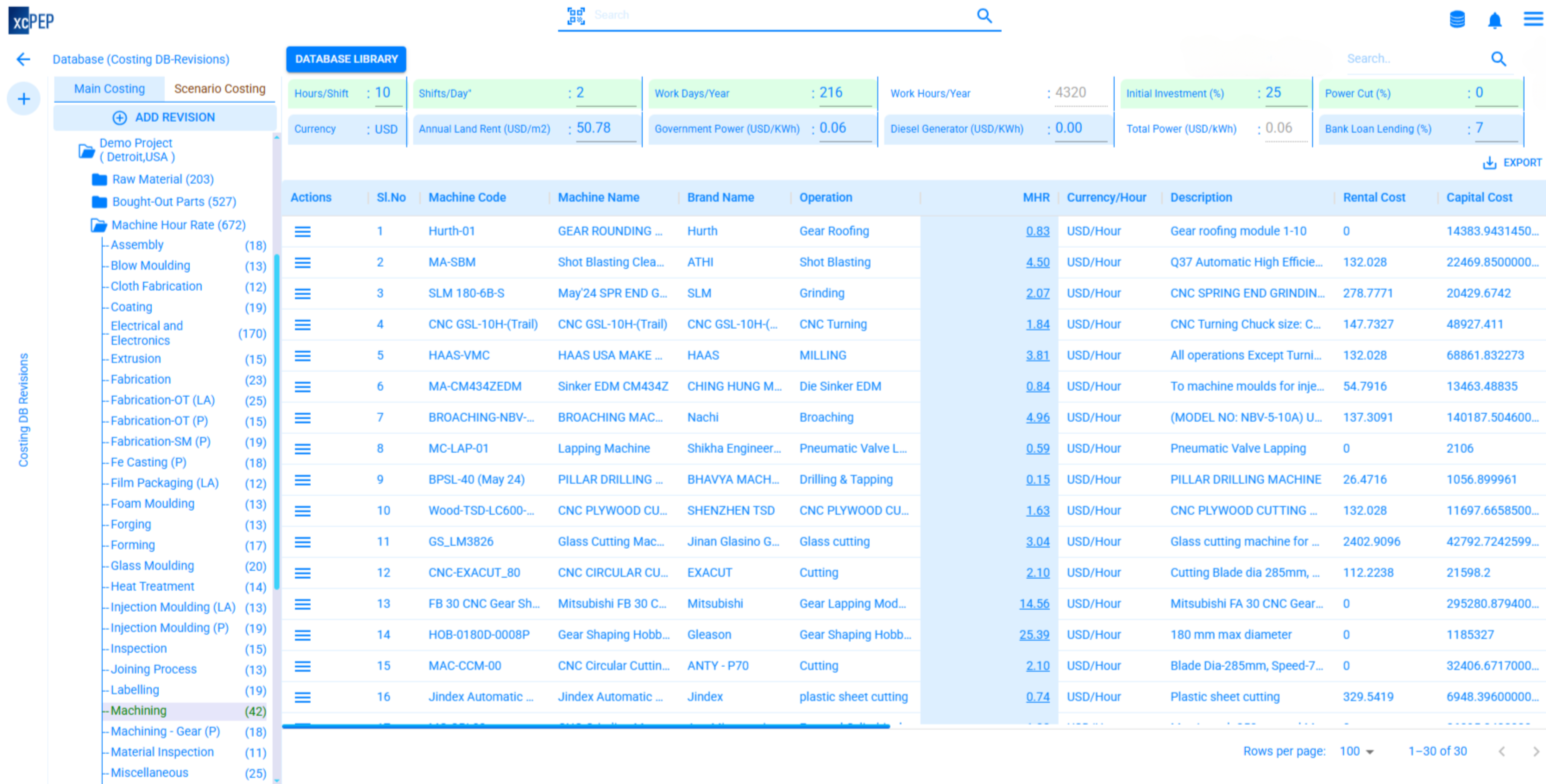

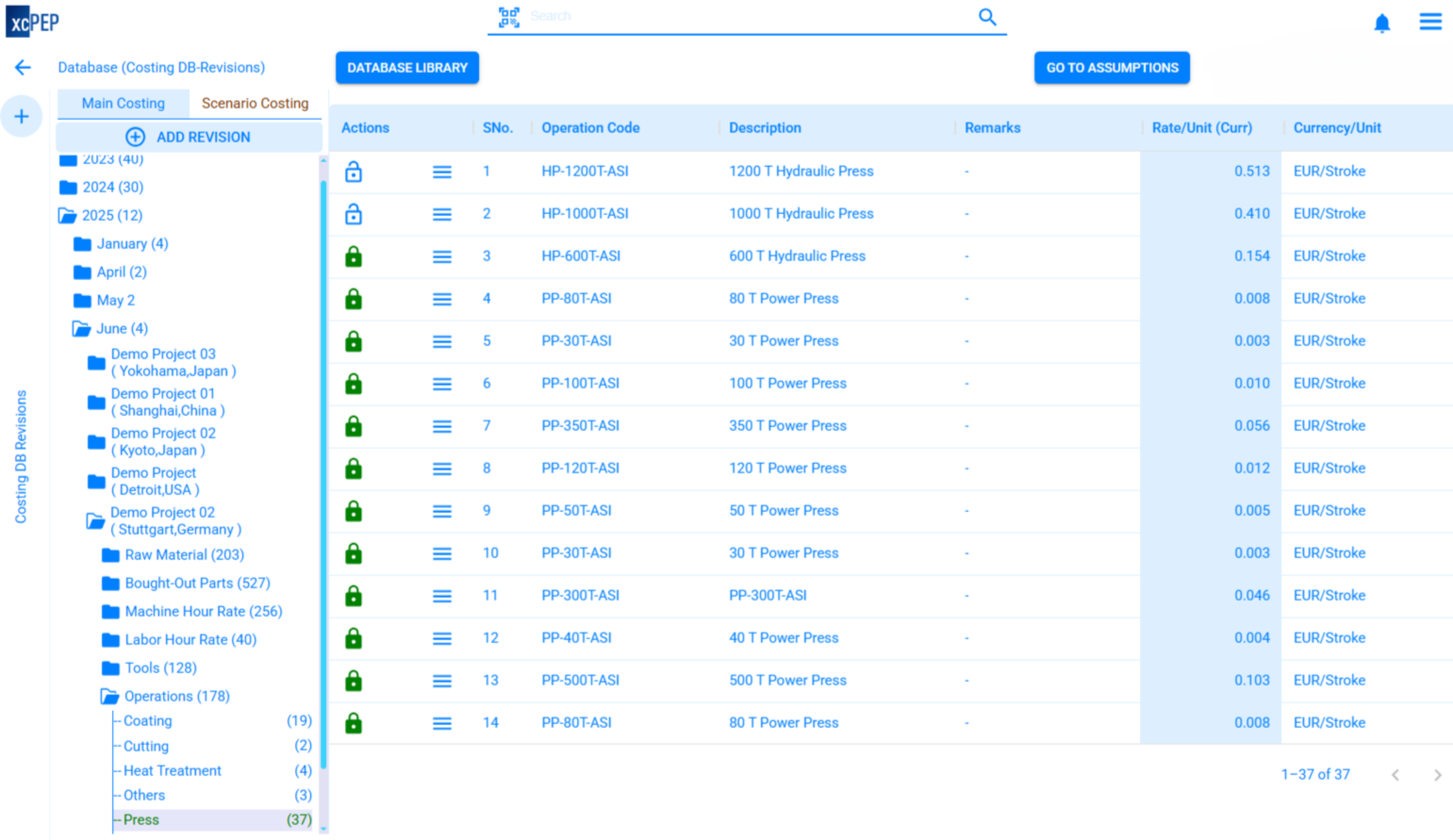

xcPROC® is the centralized database engine powering xcPEP. Built entirely by ASI’s data research team, each database is meticulously curated to be region-specific and time-specific, reflecting real-world manufacturing conditions, not generic multipliers.

Machine Database

Contains structured cost parameters for manufacturing equipment, including brand, capital/rental costs, and utility consumption to calculate the machine hour rate (MHR).

Wage & Salary Database

Provides region-wise labor hour rates with detailed breakdowns for skilled, semi-skilled, and unskilled labor.

Raw Material Database

Contains structured data for materials, including grade, sub-grade, initial shape, density, and cost per unit with currency.

Operations Database

Stores cost and rate data for standard manufacturing processes like machining, welding, and coating.

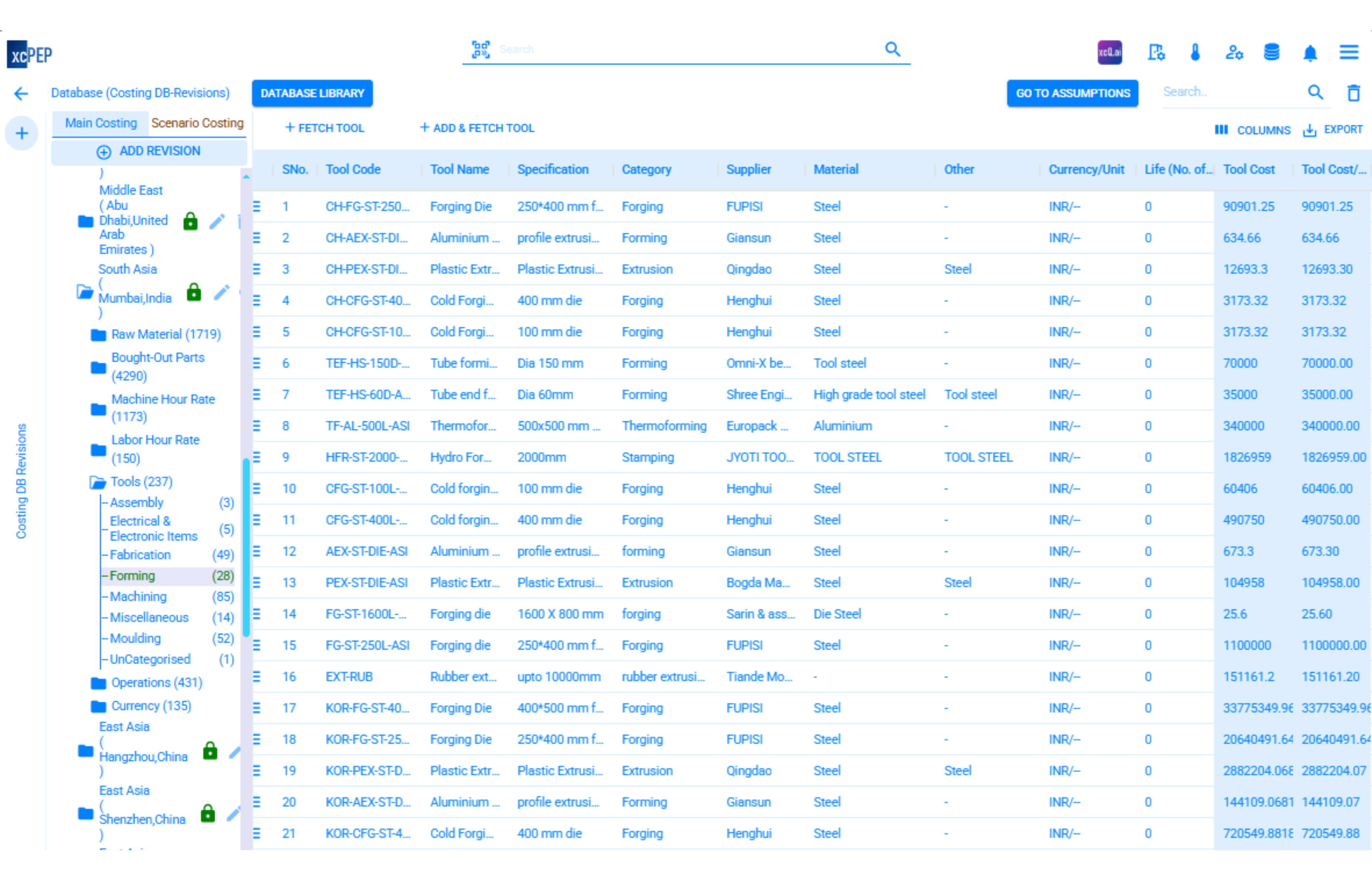

Tools Database

Captures tool-level information including specifications, supplier, cost, and usage life for depreciation models.

BOP Database

A library of standard bought-out parts like fasteners, resistors, capacitors, and connectors, pre-costed and ready to use.

Custom Database

Need something specific? We build custom databases for packaging, logistics, and more.

A Library That Mirrors the Real World

Explore the full range of manufacturing processes supported by our proprietary cost models. We provide near 100% commodity coverage-from primary operations to final assembly-including deep-costing capabilities for complex electrical and electronics components.

| Process Group | Processes List |

|---|---|

| Assembly Processes |

Show assembly processes

Manual Assembly

Automated Assembly

Sub-Assembly Integration

Wiring Harness Assembly

Connector Assembly

PCB Assembly

Motor Assembly

Gear Assembly

Bearing Assembly

Spring Assembly

Compressor / Pump / Valve Assembly

Busbar Assembly

Battery Assembly

Freezer / Refrigerator Assembly

Crankshaft & Bearing Assembly

Differential Assembly

Stator Winding & Assembly

Terminal Assembly

Housing Assembly

Mechanical Part Assembly

|

| Machining & Metalworking |

Show machining processes

Turning

Milling

Drilling

Boring

Reaming

Threading

Tapping

Knurling

Broaching

Shaping

Hobbing

Shaving

Grinding

Buffing & Polishing

Lapping

Facing

Gear Grinding / Hobbing / Shaping

Slot Cutting

Profile Cutting

Shearing

Saw Cutting

Punching

Blanking & Piercing

Deep Drawing

Coining

Deburring

Engraving (Laser / Mechanical)

Jig & Fixture Machining

|

| Forming, Casting & Moulding |

Show forming / casting processes

Forging (Open Die / Closed Die / Cold / Hot)

Extrusion (Metal / Plastic / Rubber)

Roll Forming

Sheet Metal Forming

Bending / Joggle Forming

Press Forming

Swaging

Spinning

Calendaring

Stamping (Progressive / Compound / Transfer)

Tube Forming (Flaring / Flattening / End Forming / Bending)

Casting & Moulding

Die Casting (Aluminum / Zinc / Brass)

Sand Casting

Investment Casting

HPDC

Injection Moulding

Blow Moulding

Compression Moulding

Rubber Injection Moulding

FRP Moulding

Foam Moulding

Glass Moulding / Pressing

Vacuum Forming

EPS Moulding

|

| Welding, Joining & Brazing |

Show welding / joining processes

MIG / TIG Welding

Spot Welding

Projection Welding

Laser Welding

Ultrasonic Welding

Brazing

Induction Brazing

Soldering

Friction Welding

Helium Leak Welding

Adhesive Bonding

Heat Shrink Fitting

|

| Heat Treatment & Thermal |

Show heat / thermal processes

Heat Treatment / Thermal Processes

Annealing (Metal / Glass / Plastic)

Quenching

Tempering

Hardening

Normalizing

Stress Relieving

Sintering

Oven Curing

Furnace Heating

Oven Drying

Cooling

Dehumidification

|

| PCB Manufacturing Processes |

Show bare PCB processes

Bare PCB Processes

PCB Drilling

Copper Deposition (Thin / Thick Layer)

Etching / Micro Etching

Lamination / Stack-up

UV Film Lamination

UV Light Exposure

Solder Mask Application & Drying

Screen Printing

Surface Finish (HASL / ENIG / etc.)

Panel Cleaning & Drying

Depaneling

V-Scoring

|

| PCB Assembly Processes |

Show PCB assembly processes

Pick & Place (Top / Bottom)

Solder Paste Application

Reflow Soldering

Wave Soldering (ROHS / Non-ROHS)

AOI (Automated Optical Inspection)

X-Ray Inspection

Conformal Coating & Curing

Manual Soldering

PCB Electrical Testing

|

| Surface Treatment & Coating |

Show surface / coating processes

Surface Treatment & Coating

Painting

Powder Coating

Electroplating (Nickel, Zinc etc.)

Anodizing

Phosphating

E-Coating

Spray Coating

Chrome Plating

Black Oxide

Masking

DLC Coating

Anti-Reflective / High-Reflective Coatings

Vacuum Coating

Conformal Coating (PCB)

Surface Grinding & Polishing

Coating Thickness Test

Salt Spray Test

|

| Textile & Soft Material |

Show textile / soft processes

Stitching

Embossing

Coating

Fabric Cutting

Fabric Printing

Webbing Cutting

Knitting / Weaving

|

| Plastics & Rubber Processing |

Show plastics / rubber processes

Plastic Extrusion

Plastic Injection Moulding

Thermoforming

Rubber Extrusion

Rubber Compression Moulding

Rubber Preforming

Plastic Welding

Film Cutting / Sealing

Polybag Blowing & Cutting

|

| Inspection, Testing & Qualification |

Show test / inspection processes

Inspection & Testing

Visual Inspection

Dimensional Inspection (CMM)

Electrical Testing

Continuity / Insulation Resistance Test

High Voltage / Hipot Test

Functional Testing

Load / No-Load Testing

Vibration Testing

Impact Testing

Leak Testing (Helium / Pressure / Vacuum)

Thermal Shock Testing

X-Ray Testing

Dielectric Testing

IP Testing (IPx5 / IP9K)

Environmental Testing

|

| Material Prep & Primary Ops |

Show material preparation processes

Material Preparation & Raw Material Handling

Mixing (Slurry, Masterbatch, Batching)

Pelletizing

Powder Sieving

Raw Material Analysis

Material Testing

Decoiling / Slitting

Cutting (Sheet / Rod / Wire)

Wire Drawing & Stranding

|

| Packaging & Logistics |

Show packaging / logistics processes

Packing

Vacuum Sealing

Tape & Reel Packing

Labelling & Marking

Polybag Packaging

Box Packing

Material Handling

Palletizing

|

| Supporting & Overheads |

Show supporting processes

Tooling Preparation

Fixture Assembly

Automatic Feeding

Washing & Cleaning

Oven Drying

Cooling

Dehumidification

Overheads (Assembly / Machining / Testing)

|

New cost model development is included in your xcPEP license.

Unlike black-box software, xcPEP cost models are not hard-coded; they are fully visible and sit in the UI layer. Simply raise a request with your specific production or regional requirements, and ASI’s dedicated Cost Engineering team will build and publish the new model directly into your instance in real time-all included in the annual license fee.

Advanced Data Capture Hardware

Developed by ASI to accelerate teardown and costing workflows. These tools integrate directly with xcPEP to ensure speed, repeatability, and data reliability.

AI-Based PCB Component Identification

A calibrated imaging setup and AI automatically detect, classify, and match all mounted components against the xcPROC database to populate the BoM without manual tagging.

Bounding Box Dimension Capture System

A laser-based setup captures a part's length, width, and height without physical contact, transferring real-world dimensions directly to xcPEP for extrusion and packaging models.

Automated Projected Area Capture System

Captures a part's 2D projected area, a key parameter for injection moulding (machine tonnage) and sheet metal (blank sizing, painting), replacing slow, error-prone manual estimation.

Built for Costing & Procurement Teams

Purpose-built for procurement, cost engineering, and sourcing teams to run Should Costing, supplier negotiations and cost-down programs at scale.

New Part Development (NPD)

Generate cost estimates from drawings before RFQ to set targets and catch high-cost design decisions early.

Target Costing

Set data-driven cost targets for new products and track component-level costs against budgets in real time.

Cost Lab Setup

Establish an in-house cost lab. We configure the platform and train your team in a Build-Operate-Transfer model.

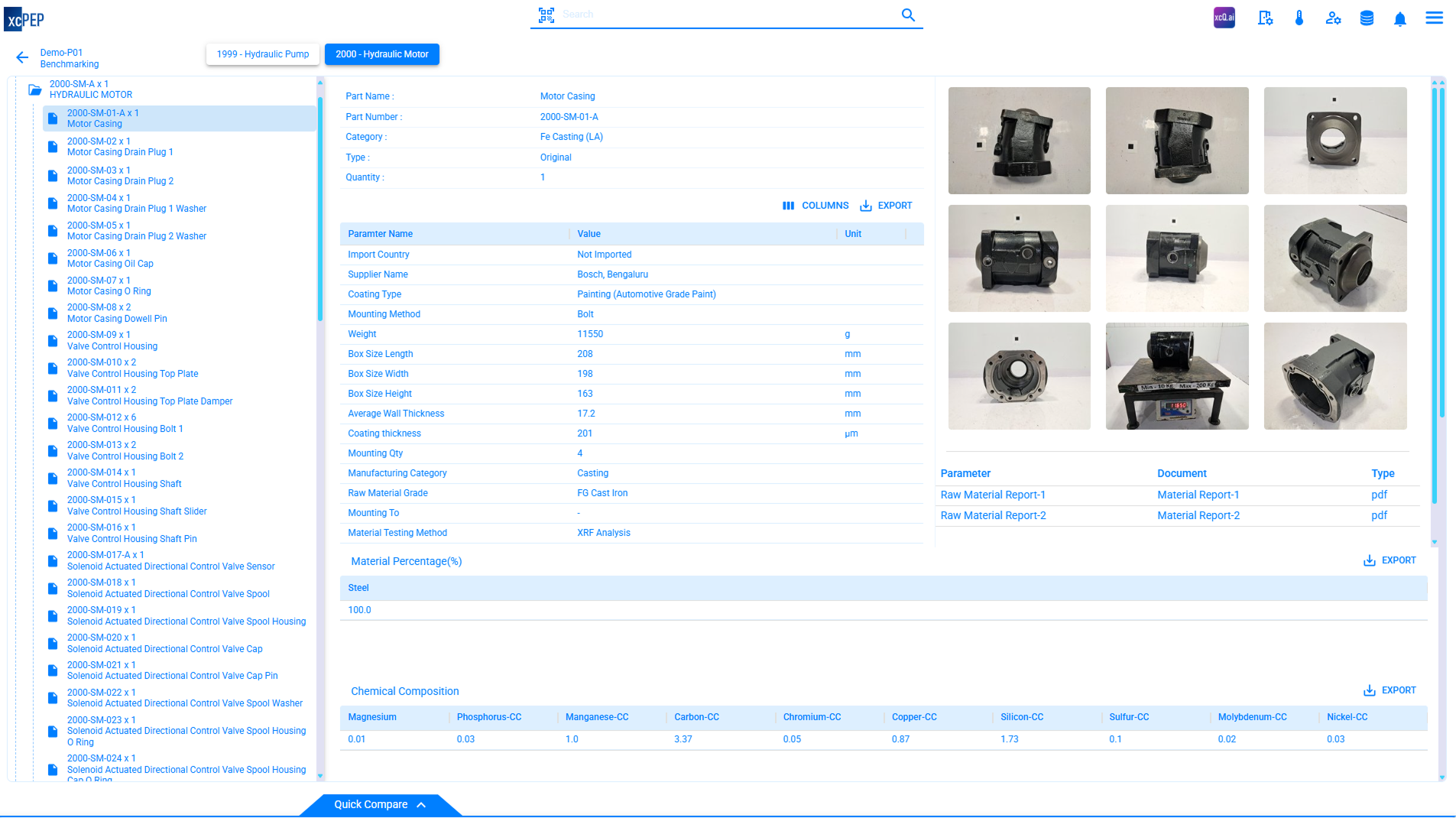

Competitor Benchmarking

Perform teardown analysis of competitor products to identify cost gaps and evaluate alternative design choices.

Cost Reduction Digitization

Move cost-saving ideas from spreadsheets into a centralized, trackable Idea Tracker module integrated with your models.

Scenario Costing & Analysis

Simulate the cost impact of changing tolerances, materials, or suppliers to make the best design trade-offs.

Idea Generation Engine

xcPEP’s intelligent idea engine ingests benchmarking outputs, compares multi-dimensional cost parameters, and instantly surfaces high-impact opportunities ranked by feasibility, savings potential, and implementation effort.

Proprietary Parts Costing for Supplier Negotiation

xcPEP gives clear, data-backed cost estimates for proprietary parts, helping teams validate supplier quotes and negotiate confidently.

Manufacturing Data Layer for AI

xcPEP generates a validated manufacturing data layer that your internal AI can directly use across procurement, engineering, and operations - helping teams see the full picture and make faster, smarter cost decisions.

xcPEP vs Legacy Tools

Parametric tools are black boxes. Excel is unmanageable. xcPEP is purpose-built for real-world should-costing, combining structure, transparency, and teardown-ready inputs.

| Capability / Feature | xcPEP | Legacy costing / parametric tool | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Core costing & process depth

|

|||||||||||||||||

Cost model architecture (UI-layer models) Key Differentiator

|

|||||||||||||||||

Data inputs, RM, machine hour and xcPROC service

|

|||||||||||||||||

Performance, usability and ownership

|

|||||||||||||||||

API and integration capabilities

|

|||||||||||||||||

Security, compliance and deployment

|

|||||||||||||||||

Commercial, support and rollout

|

|||||||||||||||||

Note: xcPEP models are delivered through the UI and updated centrally by ASI. Customers can raise tickets to get new or variant process models. These are released as per the defined turnaround time and become visible in the customer tenant in real time.

Your Data. Your AI. Unleashed.

xcPEP generates the structured, validated manufacturing data layer your enterprise tools are missing. Stop feeding your AI generic numbers; give it real manufacturing logic.

xcPEP Platform

Your "Glass Box" engine for costing & manufacturing logic.

xcPEP backend as structured data layer

BOMs, Processes, MHR, LHR, Tooling, & Routings

Your Internal Tools

BI Dashboards

Enterprise AI

ERP & PLM

Analytical Tools

Your Business Logic, Not a Black Box

xcPEP’s Templatization Approach

- ✓ Custom-Built for Your Internal Logic

- ✓ Reflects Your Unique Supply Chain

- ✓ 100% Transparent & Defensible

- ✓ Flexible, Editable Models in the UI

Legacy "Black Box" Costing

- ✕ Uses Generic Algorithms

- ✕ Ignores Your Internal Logic

- ✕ Fails in Real Negotiations

- ✕ Hard-coded & Inflexible

At ASI, we believe you should never have to guess why a cost is what it is. We reject the "black box" model. Instead, we partner with your experts to transform your unique production logic, quality standards, and regional data into a transparent, configurable engine. The result isn't just a number-it's a living, auditable model of your business that you can use to defend every negotiation with total confidence.

Enterprise-Grade Security & Compliance

We're built on a foundation of security. From SOC 2 compliance to complete data sovereignty, xcPEP is designed to meet the rigorous standards of global enterprise IT teams.

SOC 2 Type II Compliant

Our platform is audited and certified, ensuring your data is managed with enterprise-grade security and confidentiality.

ISO 27001:2022 Compliant

We adhere to the highest international standards for information security management, protecting your sensitive IP.

GDPR & CCPA Compliant

We are committed to data privacy, with robust processes in place to meet global data protection regulations.

Data Sovereignty

Your data, your rules. xcPEP can be deployed in your own cloud infrastructure (AWS/Azure) for complete control.

SSO Ready

Integrate with your existing Single Sign-On providers (like Okta or Azure AD) for seamless and secure team access.

Role-Based Access Control

Granular permissions control who can view, create, or edit models and data, ensuring data integrity.

Frequently Asked Questions

What teams usually ask when evaluating xcPEP.

Unlike rigid templates, xcPEP uses editable models, teardown-ready inputs, and plant-level logic. Here are the questions we get from procurement heads, engineers, and cost controllers evaluating our platform.

xcPEP is provided as an enterprise-level SaaS (Software as a Service) platform, billed annually. The subscription includes all platform updates, new cost model development, and access to our dedicated support teams.

xcPEP is designed for real-world manufacturing data. It only requires a few key parameters (typically 5-8) per part, which can be taken directly from manufacturing drawings or a physical teardown. Unlike many legacy tools, 3D CAD models are not required to generate an accurate cost.

Our data is continuously refreshed. Core databases, like machine specifications, are updated annually, while dynamic data, like Raw Material (RM) rates, are updated quarterly. Furthermore, the platform receives incremental updates weekly and can be updated in real-time to meet specific customer requirements.

We prioritize flexibility and data sovereignty. By default, your instance is hosted in our secure AWS cloud in the geography of your choice. For enterprises with specific compliance needs, we also offer deployment directly within your own private cloud on AWS, Google Cloud, or Azure.

xcPEP is a proven, industry-agnostic platform used by global leaders in Automotive, Off-Highway Vehicles, Home Appliances, Industrial Equipment, and Consumer Electronics. Our platform provides near 100% commodity coverage, including deep-costing capabilities for complex electrical and electronics components.

Our xcPROC database includes comprehensive, region-specific cost parameters (like Machine Hour Rates, Labor Hour Rates, and raw materials) for over 35 global regions. As part of our white-glove onboarding, we map your supply chain's footprint and proactively add any new data you require.

A standard enterprise onboarding is completed in just 4-6 weeks. This includes full platform configuration and team training. We also offer optional services to migrate your historical cost data, with a timeline based on the volume of data.

We are built on a foundation of enterprise-grade security. Our platform is fully compliant and certified for both SOC 2 Type 2 and ISO 27001, the leading global standards for information security management.

Yes. This is our core differentiator. The platform is highly configurable through the UI, allowing you to adapt cost models to your specific production logic. While every customer runs on the same stable code base, your instance is uniquely configured to mirror your business.

Start the Conversation

Email our team to request a custom demo or discuss enterprise SaaS licensing.